The C-B slurry is prepared by combining cement with a hydrated bentonite-water mixture just before discharge of the C-B. Studies of grout mix Cement-based grout mix design is commonly carried out based on volumetric ratio to avoid unpractical on-site weighting procedures 1.

Blend Mix Proportions And Blend Slurry Properties Download Table

Bentonite grouts tend to be either coarser-grind bentonites.

. Not more than 5 percent cement bentonite 46 pounds may be added. During construction of the barrier wall a trench is excavated under a head of C-B slurry. May be difficult or impossible to mix to the required bentonite content.

The addition of bentonite to a cement slurry requires additional mix water. Mix water and cement first. Cement-bentonite watersolids 4 to 1 10-6 Vaughan.

This is accom-plished by mixing the cement with the waterfirstThisiscontrarytoprocedures. Read customer reviews find best sellers. For Mix Design IS10262-1982 For Zoning of Sand.

There is no particular amount of bentonite that you must add. Cement bentonite grout mix. A design mix program is always recommended to optimize CB performance.

A typical cement-bentonite C-B slurry mixture consists of about 18 percent portland cement 6 percent bentonite and 76 percent water. Barı ş Esener Department of Civil Engineering Faculty of Engineering Pamukkale University Denizli Turkey. 20 bentonite blend 1153.

Cement bentonite grout mix. 94 lb 1 bag 1. When mixing on site its imperative to get the water volume with cement powder content right.

20 bentonite blend 124. The specimens were cast as per mix design. Mix Proportion Material Quantity kgm 3 32552 kg m 3 Water 140 kgm 3 Admixture 357 kg m 3 Fine aggregate 7508 kgm 3 Coarse aggregate 1248290 kgm Water -cement ratio 043 Before.

Day ÄBSTRÄCT Ä cementbentonite CB slurry cutoff wall is a variation of the slurry wall process that is used to create an underground barrier to stop the lateral flow of ground water and other fluids. Grout Mix for Soft Soils. A typical cement-bentonite C-B slurry mixture consists of about 18 percent portland cement 6 percent bentonite and 76 percent water.

It can be directly mixed with cement dry-blended and. Permeability test results can be found in the mix design report. It is recommended to pre-hydrate the bentonite and properly hydrate prior to mixing the cement slurry.

The density of slurry ps is related to the concentration C of bentonite by weight of mix water as follows. Cement-bentonite installations do not require a separate backfilling operation and its for this reason that this technique is sometimes referred to as one-step slurry wall construction. Adjust the amount of bentonite to produce a grout with the consistency of heavy cream.

Grout mix type for under dam curtain wall application 4. A rule of thumb is for each 1 of bentonite an additional 53 of water is required. Should the cement return to the surface with less than the acceptable amount then the tremie pipe should be moved to clear the.

In the patent document Edison says. The range of the volumetric ratio between water and cement is around 6. Drillers are accustomed to mixing water and bentonite first but this will not allow you to control the water-cement ratio.

Sample Matrix Slurry Mix Permeability cmsec AC-1 AC Mix w Bentonite 5 Bentonite 15 x 10-8 AC-2 AC Mix w Bentonite 05 Dry 5 Bentonite with 05 Dry Bentonite 20 x 10-8 AC-3 AC Mix w Bentonite 10 Dry. Portland Cement ASTM Type I or API Class A B - Portland cement is a mixture of lime alumina. To decrease the strength of the grout add more water.

See Notes Below 04. 1 to 06. Calculate a theoretical amount of cement needed prior to the beginning of the grouting operation.

Most specifications allow for a maximum of 6 gallons of water per 94 pounds one bag of Portland Type 1 cement powder. We try to mix it and depending on the depth pump it to the size of tremie pipe used at a ratio of 5⅝ to 5¾ gallons of water. Ad Browse discover thousands of brands.

Literatures review 21. CEMENT-BENTONITE SLURRY WALL MIX DESIGN Christopher R. The following table summarizes the test results.

The cement and water shall be mixed at a ratio of 52 gallons of water to one 94 lb. If the grout is too thin the solids and. Because of the relative simplicity.

Irawanfirmansyah Geotechnical 28 Jun 10 0423. Usability of sand-bentonite-cement mixture in the construction of unpermeable layer Devrim Alkaya and A. I find that by adding a comparatively small amount of fine clay to the mixture say 20 of the.

20 bentonite blend 136. Grout strength decreases with water-cement ratio and controlling this ratio is the most important factor for grouting and it is therefore recommended that the water and cement is mixed first. It can thus be concluded that using 20 bentonite blend the mix 124 at water- cement ratio 07 is the optimal mix because it has the highest ultimate compressive strength at 28days.

Physical properties of bentonite Table 3. From Well cementing II edition. Bag of Portland cement.

R an Steven R. Then mix in the bentonite. Ps pw 1 C CGp 1 where pw is the specific gravity of the mixing water assumed to be 10 and Gp is the grain specific gravity of.

Water and cement ratios greater than 07 10 by weight will segregate without the addition of Bentonite to provide a thick but pumpable grout mix. Compare to dry-blended when mixed with mix. Grout name Grout mix per m3 Water Cement Bentonite Admixture Liter kg kg Liter GIN 750 750 18 20 Backfilling 560 1400 - - Sleeve 910 250 25 - Cement-based grout mix is also used in the construction of preplaced-aggregate concrete also known as.

Bentonite - 39 lbs. Ad Let Angi match you with the best concrete and masonry pros for your next project. Neat-cement grout made with 54 gallons of water instead of 6 gallons will result in a grout that has less shrinkage and is less permeable.

73 water 5 - 6 bentonite 21 - 22 cement by weight RE. Connect with highly rated pros near you. Cubes and cylinders were casted with M30 design mix and compressive split tensile.

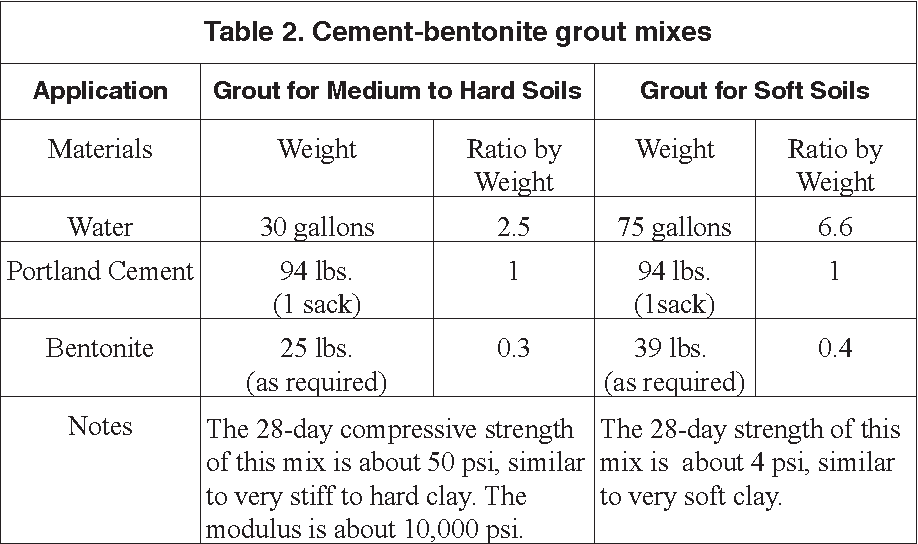

Physical properties of bentonite Table 3. Materials Weight Ratio by Weight. Experimental Studies on Concrete with Bentonite as Mineral Admixture M.

Chandrakanth Assistant Professor Department of Civil Engineering SIR C R Reddy College of Engineering Eluru. Cement bentonite grout mix. Variant with 30 bentonite blend.

Edisons proposed concrete mix design contained one part cement two parts sand and four parts 3 4-inch slag cinders along with a clay addi-tive to prevent the concrete from segregating during placement. Mix cement with water first. Neat cement and bentonite are the two main materials used for making grout slurries.

Ad Americas Supplier For Large Pond Lake Management Products. Slurry Walls Soil-Bentonite Cement-Bentonite. 1 for common applications.

Bentonite-cement mix shown optimum CS after 3 7 28. The cement-water ratio controls the strength of the grout. For contiguous bored pile wall I normally used the following mixture to get compressive strength of 150kPa.

In the patent document Edison says. Hooked end steel fibers were also included at. If sand is to be used as filler the weight ratio of.

Are possible after 90 days of curing. Mix Design Rules In order to keep field procedures simple the emphasis should be on controlling the water-cement ratio. Estimated water content 186 3100 x 186 1916 kg m 3 Step 4 Selection of Cement Content Water-cement ratio 05 Corrected water content 1916 kg m 3 Cement content From Table 5 of IS 456 Minimum cement Content for mild exposure condition 300 kgm 3 3832 kgm 3 300 kgm 3 hence OKThis value is to be checked for durability requirement from IS.

Accepted 9 May 2011 The aim of this study is to prepare a mix that can be used in impermeable fill as an alternative to clay.

2 Summary Of Cement Bentonite Grout Ratios Download Scientific Diagram

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Concrete Mix Design Used For Laboratory Tests Download Table

Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved

Mixture Designs Proportions Of Plastic Concrete Mixes Download Table

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Mixture Designs Proportions Of Plastic Concrete Mixes Download Table

0 comments

Post a Comment